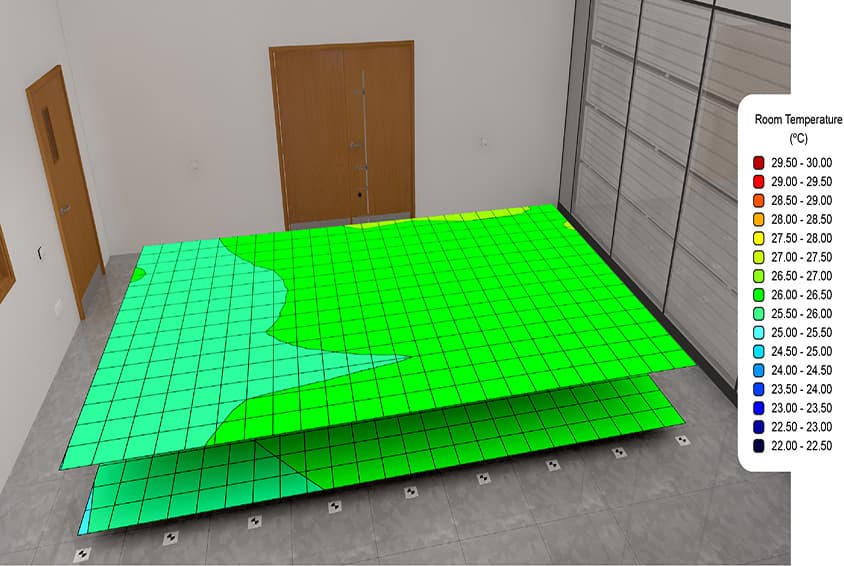

Frenger's extruded aluminium Hydroplank™ Chilled Ceiling solutions, allow large portions of the roof soffit to be activated to provide uniform cooling and heating into the occupied space, with minimal air movement and therefore exceptional Thermal Comfort with the highest performance possibilities on the market for such raft and/or ceiling systems.

When a full ('wall to wall') plank ceiling aesthetic is required, the activated raft sections are fully factory assembled by Frenger® and delivered as complete units. The 'wall to wall' dummy sections are also delivered in factory assembled sections complete with key slot mounting brackets to enable easy removal should you wish to access the ceiling void at the sides and ends of the activated raft sections.

Activated raft sections can be fully cooling or fully heating if a 2-pipe system is desired and appropriate switch over control valve from CHW to LTHW is utilised.

Alternatively, a 4-pipe system can be adopted for each raft where approximately 70% of the waterways (15mm OD copper) are a closed cooling circuit with its own flow and return tails (2 pipe connections for Cooling) and approximately 30% of the waterways (15mm OD copper) are a closed Heating circuit with its own flow and return tails (2 pipe connections for Heating).

The Hydroplank™ Chilled Ceiling uses copper tube from Frenger's bespoke in-house full CNC automated "State of the art" serpentine bending machine, which produces seamless sinusoidal copper coils with no risk of leaks as there are no joints whatsoever as each serpentine coil comes straight off one thousand metre drums of copper, as showcased in the image above.

The copper tubes fit directly into the pipe seat of the extruded aluminium "Planks" which have been designed to give optimal metal-to-metal contact to ensure maximum heat transfer.

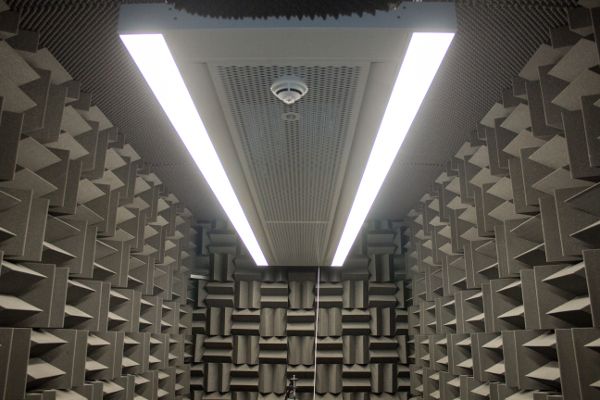

Frenger's Hydroplank™ Ceiling solutions can be supplied as stand-alone rafts or integrated into our full ceiling solution for a clean visual aesthetic. Frenger® also offer their LED luminaries which are designed to seamlessly integrate into their heating and/or cooling Hydroplank™ ceiling rafts.

Frenger® have made use of their MSCB (Multi-Service Chilled Beam) extruded polycarbonate lighting technology to develop a slimline LED luminaire to operate with an extruded polycarbonate diffuser optic that is the same profile as their extruded aluminium heating and/or cooling plank sections. With the approach clients and/or professional teams can choose alternative lighting solutions

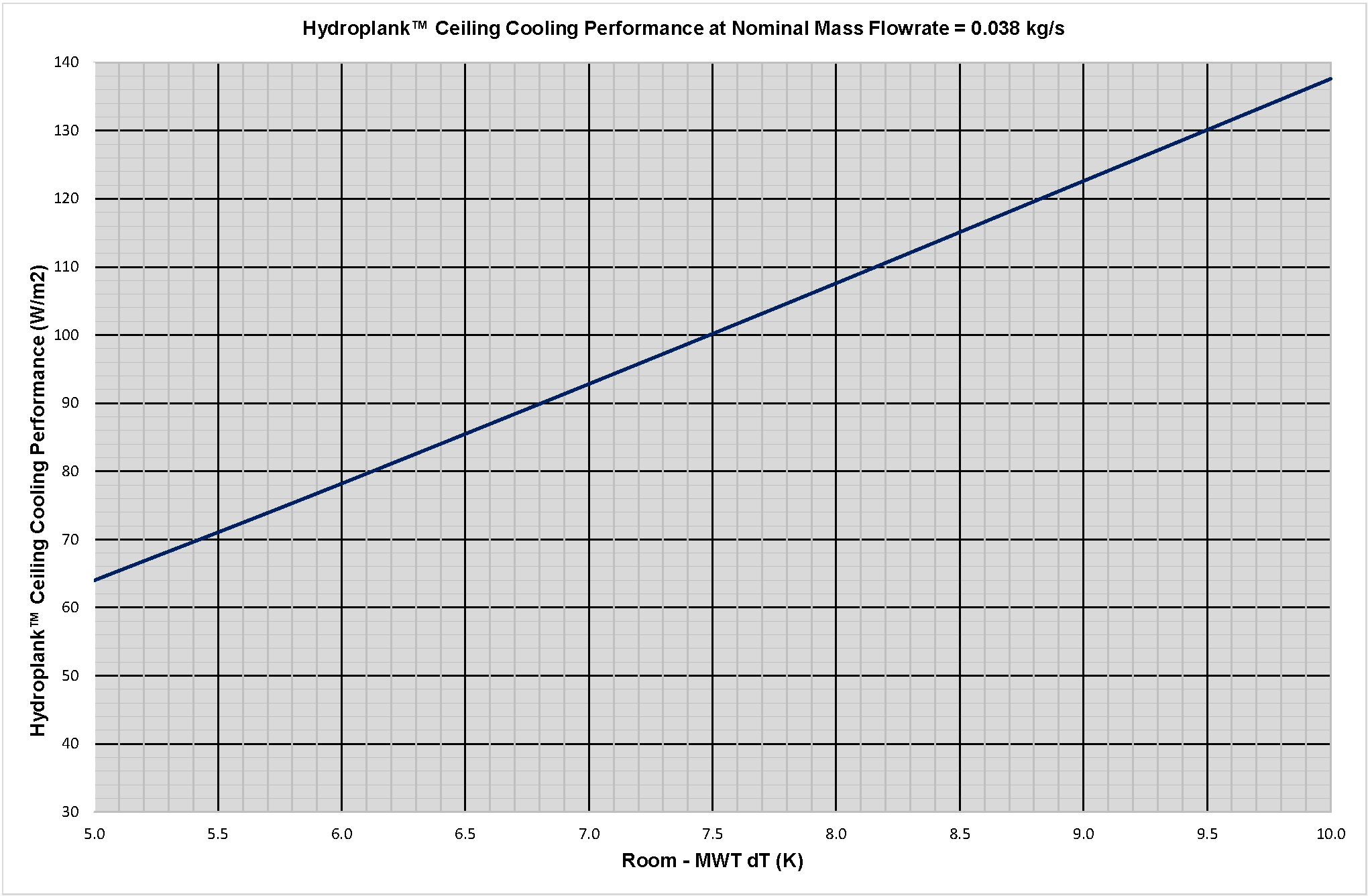

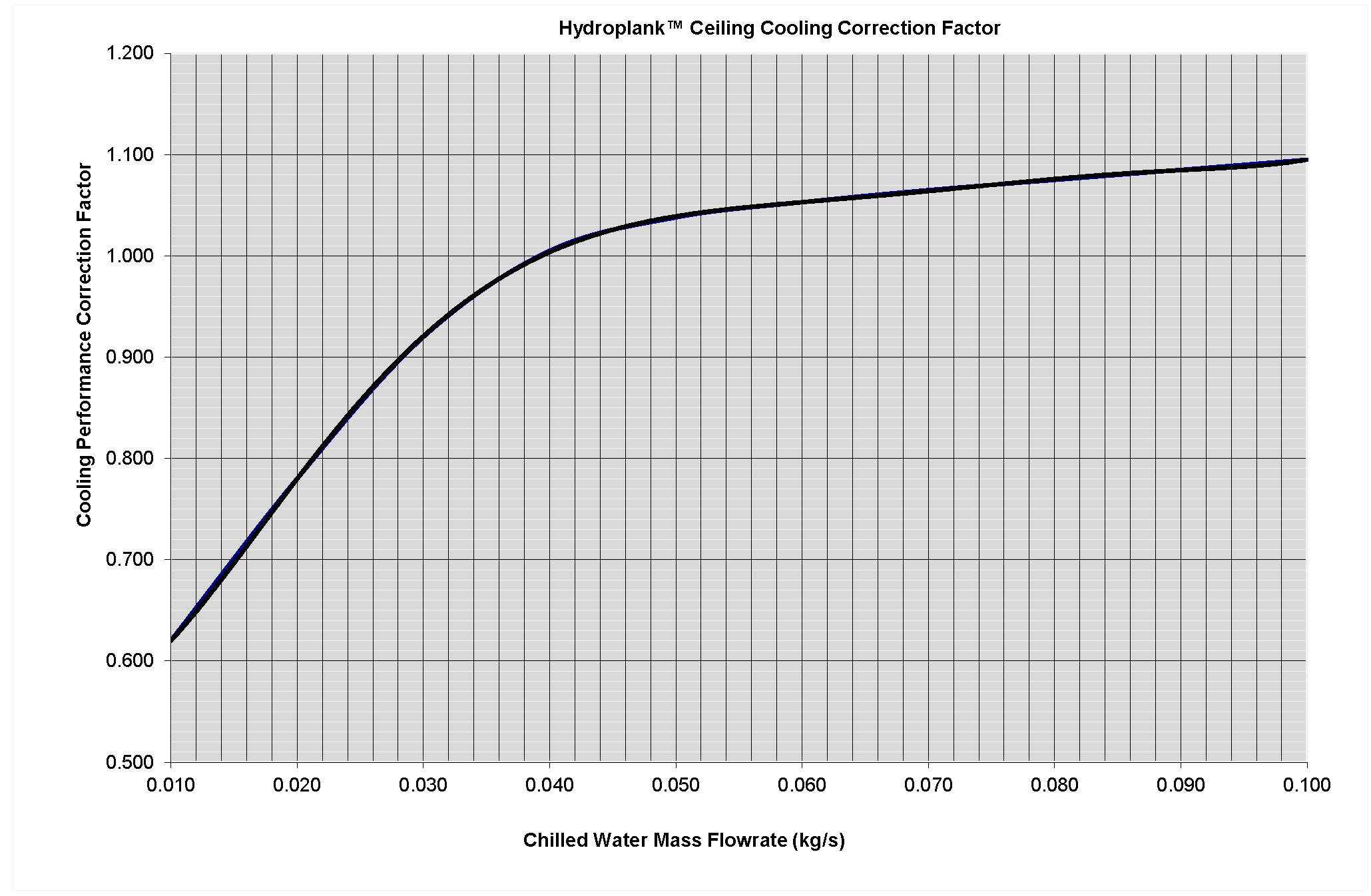

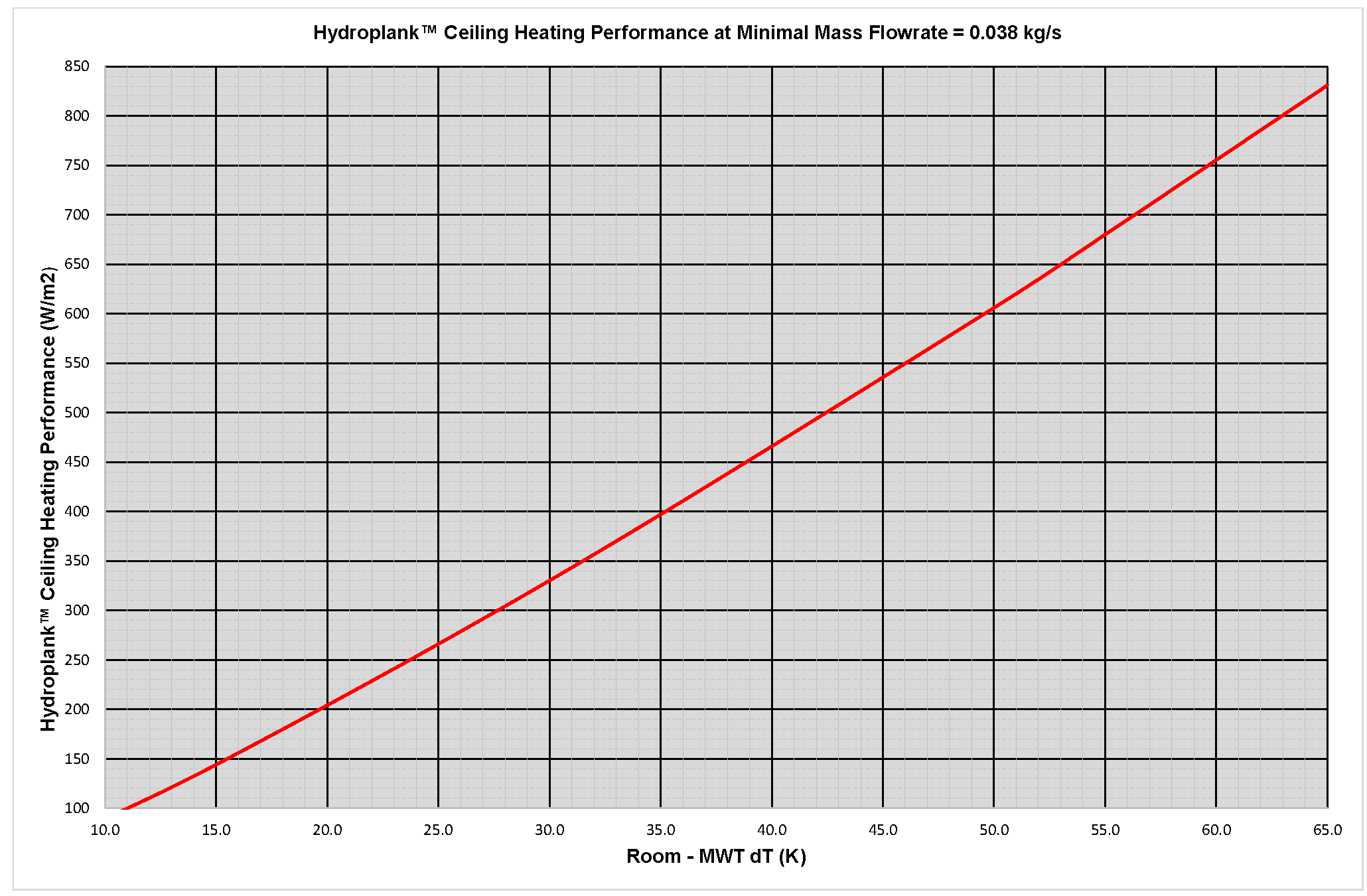

Product Performance

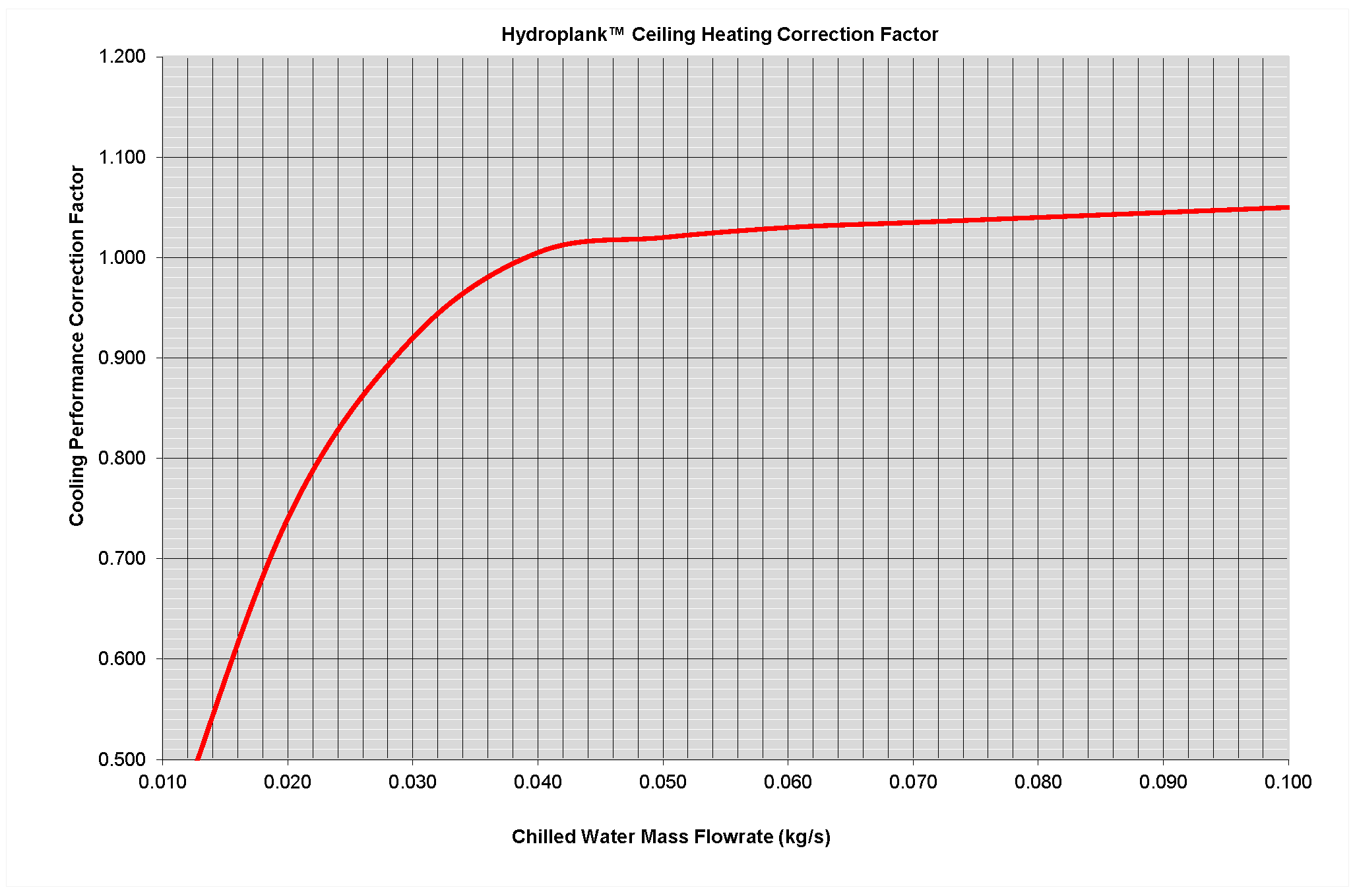

Below is a Hydroplank™ chilled ceiling cooling and heating performance graph, as well as a cooling and heating correction graphs. Note: Cooling performance should be multiplied by the "correction factor" table below dependent upon how many chilled raft sections are linked together in series for total chilled water mass flow rate.

In-house Testing Facilities

At Frenger's Pride Park Technical Facility in Derby, UK, they have in-house Photometric Lighting Laboratories for mapping the lighting distribution (Polar Curve) and an Integration Chamber for proving the LOR (light output ratio) to complement their three in-house Climatic Laboratories and an Acoustic Laboratory.

If you require any further information, or have a project to discuss, please contact us on +44(0)1332 295 678 or sales@frenger.co.uk as our technical team are here to assist. Frenger Systems® also offer in-depth Remote Design Support Meetings with our design engineers located at our UK headquarters in Pride Park, Derby.